Steel company chooses BB Cranes

This article has been supplied as a media statement and is not written by Creamer Media. It may be available only for a limited time on this website.

( Virtual Showroom )BB Cranes is to manufacture six overhead cranes for steel distributor D&E Group, for installation in new warehouses being built in Cape Town and George.

The additional warehouses will meet increasing demand by engineering firms, construction companies and general industry for D&E Group’s product ranges in mild steel, aluminium and stainless steel.

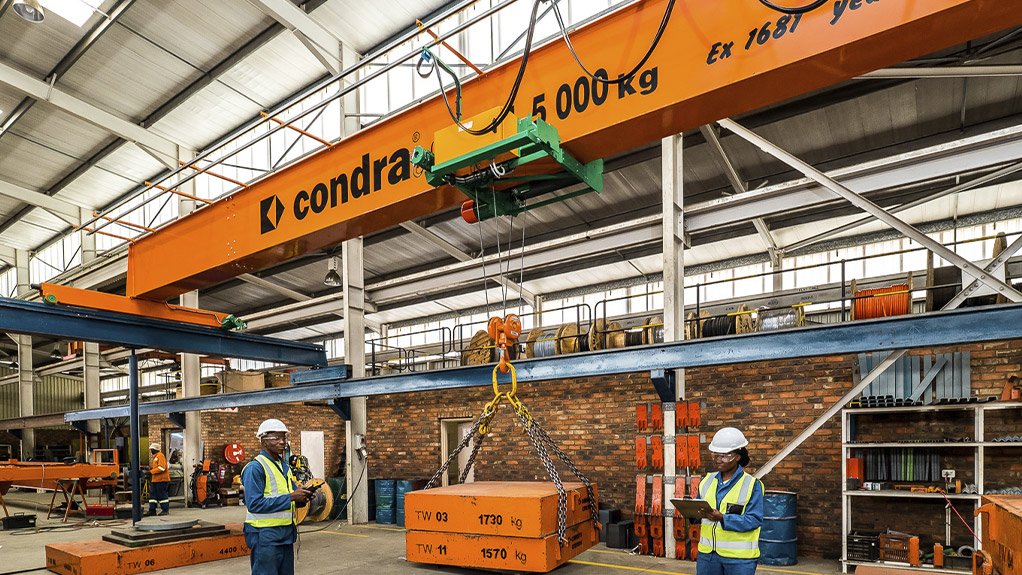

D&E’s warehouse cranes will be a mix of 8 and 5-tonners designed as single-girder electric overhead travelling machines. Condra will manufacture them to FEM class 2M standard, the classification for medium to heavy-duty service. The cranes will incorporate larger diameter wheels and miscellaneous other components on the hoists and end-carriages to ensure durability under conditions of intensive usage. Lifting heights will be around 6,5 metres. Girder spans will range between 12 and 20 metres.

Stephen Brink Jnr, senior sales executive at BB Cranes, explained that local manufacture helped win the D&E order.

“Because we manufacture in Cape Town, customers get a short lead time on a new crane. They also gain access to readily available spare parts for maximum crane uptime. We deliver spares within 24 hours,” he said.

“If a crane is to be cost effective, downtime has to be minimised,” he expanded. “But users who buy foreign cranes sometimes don’t take into consideration how much downtime will cost them if the crane is idle for long periods while spares are imported from abroad. Our spares are made locally, so delivery is almost immediate.”

Commenting on manufacturing capacity, Brink claimed that BB Cranes can deliver a new crane between eight and twelve weeks from date of order.

“Our competitors can rarely deliver in less than sixteen weeks,” said Brink. “So, because crane users often leave their lifting equipment orders until the last minute, having the shortest lead time gives us significant competitive advantage.”

Asked about expansion plans at BB Cranes, Brink announced that the company has recently added 400 square metres of factory floor space to its Rivergate premises.

“This extra space is allowing smoother production of an order book that continues to grow,” said Brink.

“We have employed an additional fabricator, and we have ongoing training programmes in place for factory staff.”

BB Cranes was founded in 1992 to marry Cape Town-manufactured crane girders and electrification systems to technically complex hoists, crabs, end-carriages and other crane components supplied by Johannesburg-based Condra, saving customers the cost of transporting a complete crane between Gauteng and the Mother City.

BB Cranes became majority-owned by Condra in 2016, and wholly owned in 2022. The company is currently working towards ISO 9001:2015 certification to match that held by Condra.

Comments

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation