Manufacturer introduces new conveyor belt cleaner

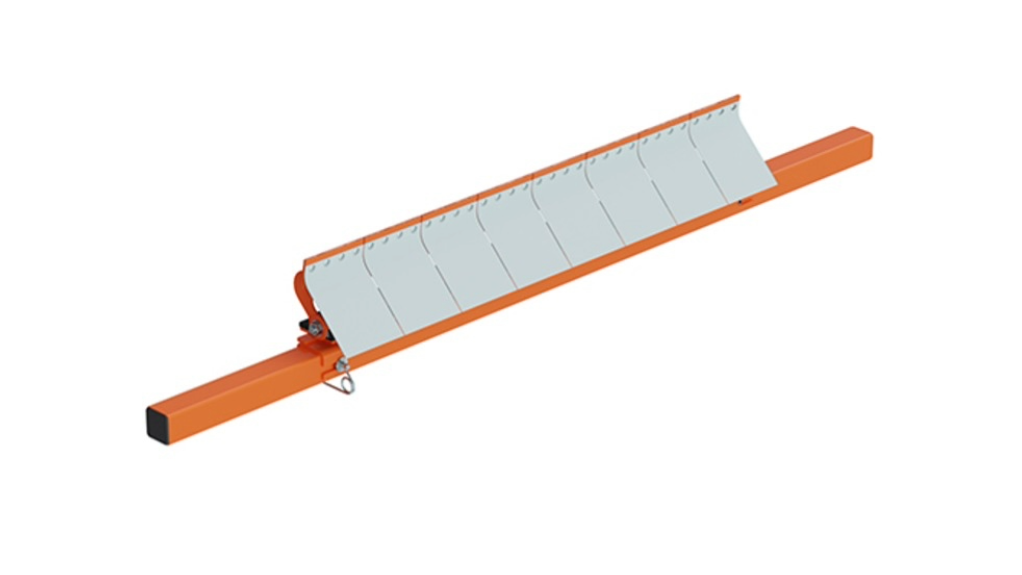

SQC2S ORION CLEANER A mounting assembly secures the secondary cleaner to the stringer

DEFLECTOR SHIELDS The deflective shields mitigate buildup on the assembly by ushering loosened material toward the discharge chute

In an effort to reduce dust carry-back and lower overall maintenance time, global leader of belt conveyor accessories Martin Engineering, has launched the next generation of secondary conveyor belt cleaners – the Martin SQC2S Orion Secondary Cleaner.

Designed to withstand the stress of heavier loads carried on wider, thicker belts at higher speeds, the Martin SQC2S Orion cleaner features individually cushioned tungsten carbide blade cartridges for effective cleaning without risk to the belt or splices.

A two-tiered tensioning system means minimal adjustments and monitoring throughout the life of the blade. The heavy-duty blades are mounted on a slide-in and/or slide-out assembly. The result is improved belt cleaning with less dust and reduced maintenance, enabling greater workplace safety at a lower cost of operation.

The slide-in and/or slide-out design also enables a single worker to perform maintenance with easy access outside of the conveyor structure, eliminating the need to crawl underneath or awkwardly reach inside. This greatly improves workplace safety and reduces the amount of time and labour required for maintenance.

“We field tested the Orion over several months side-by-side with competitor designs in punishing mining environments and found that the new design significantly outperformed the competition,” says Martin Engineering conveyor products manager Dave Mueller.

“At the end of the testing period, customer participants started the process of replacing all their heavy-duty secondary cleaners with the Orion. We now view this design as the future of our secondary cleaner line,” he adds.

Secondary cleaners play an essential role in the belt cleaning process by significantly reducing the volume of dust and fines dropped as carry-back on the belt return.

Primary cleaners release most of the abrasive material remaining on the belt after discharge. Located below the head pulley just behind the primary, secondary cleaners scrape off the fines and dust that hide in cracks and divots in the belt. Carry-back is attributed with many environmental and operational issues such as air quality violations, fouling of rolling components and machinery, and increased labour for cleanup and maintenance.

The Martin SQC2S Orion Secondary Cleaner is appropriate for all bulk handling material applications. The unit is made up of individual 152.5 mm blades mounted on a square steel tube assembly. Not designed for reversing belts, it is suitable for 457 mm to 2 438.5 mm belt widths, belt speeds up to 6 m/s, and temperatures up to 121 ºC.

“What sets this unit apart from others on the market is the innovative, dual tensioning system, with independent heavy-duty tungsten blades which are game-changing design features,” Mueller explained.

He adds that “the first level of tensioning is supplied to the entire assembly using the heavy-duty SQC2S Tensioner which applies light upward torque evenly across the belt profile for less friction and no wear on splices”.

Additionally, the second level of tensioning is on the individual blade assembly. Each Orion blade assembly is attached to a steel square tube assembly which is secured on a mounting plate. The square tube houses a rubber tensioner with a torsion arm bolted to each side. A specialised tungsten blade is attached to the arm.

The entire system is mounted at a 90° angle, then tensioned, so each blade is vertical and perpendicular to the belt. As the belt runs, each blade assembly adjusts independently to precisely match the belt’s profile, permitting them to compensate for camber, flaws, blemishes, and stubborn material stuck to the belt’s face. To accommodate belt cupping and other uneven surfaces, the blade assemblies can be individually adjusted to match the belt profile.

The blades are specially designed for heavy-duty abrasive applications in both dry and wet environments. Tested on hard-rock and slurry belts, the Orion blades offer “superior cleaning results with a longer equipment life”. This is owed to the rugged tungsten carbide core surrounded by mild steel. Blades are also available in stainless-steel for specific corrosive materials.

Further, the blade design features an attached deflector shield made from polypropene or rugged nylon for high temperature applications. Mounted directly to the blade in an outward scoop design, the shield ushers loosened material toward the discharge chute. This mitigates buildup on the assembly, extending the blade’s effectiveness and reducing the amount of maintenance.

“Martin Engineering products are developed to improve efficiency and safety, without compromising belt health. This design gives customers more options and superior results, regardless of the material or the process,” Mueller concludes.

Comments

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation