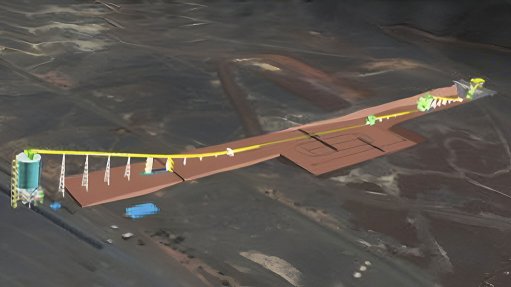

Tip-to-train loadout station

Open pit mining of the F’derick deposit began in 1967, marking a significant chapter in Mauritania’s industrial history. After a 38-year break, the Societe Nationale Industrielle et Miniere (SNIM) resumed reconnaissance of the F’derick deposit in 2006, uncovering valuable hematite resources. Now SNIM is set to restart operations, signalling a new era for the region.

TAKRAF has been awarded the contract to deliver the complete materials handling system for the iron ore mine. This project involves the design, engineering and supply of crushing and screening units, complete with belt conveyors and accessories, and the train loadout station, ensuring a seamless operational flow.

TAKRAF South Africa appointed John Thompson which is a division of ACTOM, as a sub-contractor. John Thompson’s scope extends to engineering, designing and manufacturing dust extraction systems for the iron ore plant in the Tiris Zemmour region of Mauritania.

Given the region’s harsh desert climate and scarce water resources, effective dust management is crucial. John Thompson’s Pulse Jet Collector Systems, equipped with plant ducting, material handling and clean air extraction fans, are designed to tackle this challenge by extracting nuisance dust and recycling the product back to the system. The scarce water supply was a contributing factor in the choice of extraction equipment supply, as bag filters require no water supply as opposed to wet scrubber systems, which are also available in the product range.

With over 53 years of experience in the air pollution control (APC) industry, John Thompson prides itself on delivering robust, well-engineered solutions. “We are excited to collaborate with TAKRAF South Africa and contribute to the success of this pivotal project,” remarked John Thompson APC technical sales engineer Warren Turner.