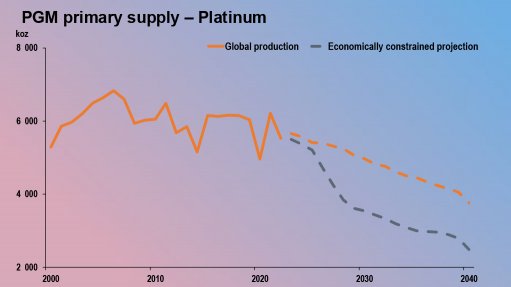

Graph showing projected downward path of platinum.

JOHANNESBURG (miningweekly.com) – Under current market conditions, many platinum mines will close prematurely owing to a lack of financial resources – and even without financial constraint, closure of depleting mines will result in platinum availability being considerably below the level that has prevailed for the past quarter century, Minerals Council South Africa VP Paul Dunne informed last week’s Shanghai Platinum Week audience.

Displaying a graph projecting two global platinum scenarios, Dunne said the lower declining darker dotted line shown in the image above would be platinum’s downfall should current platinum group metals (PGM) pricing persist.

The slide depicts the newly mined platinum production over the last 24 years in the solid line, as well as two scenarios of future milled platinum production.

The orange dotted line scenario depicts the view of milled platinum production when there are no financial constraints and mines cease to produce owing to reserve depletion.

“This is the maximum production, in our view, without new projects,” Dunne said of the dotted orange line, which includes supply projection from mines that have been announced and started, as well as those in production now.

But even as can be seen from the dotted orange line projection, current mining investment will not be able to offset the loss of production from the old mines passing on, Dunne spelt out as CEO of Northam Platinum, which has grown by more than 300% since 2014.

The second scenario, shown by the darkish dotted line, illustrates the projected production collapse on the way if the current uneconomic PGM prices persist.

Anticipated is that many mines will be closed prematurely owing to a lack of financial resources.

“Under current market conditions, the blue line can be so,” Dunne reiterated, while conceding that the eventual outcome may be somewhere in between, but still worryingly down.

This graph shows our view of future mined palladium production across the world.

The same two scenarios were also shown for palladium production across the world, albeit with the palladium PGM falling at a slower pace than forecast for platinum over the next 20 years, owing to the relatively smaller exposure palladium production has to Southern Africa’s economics.

But, in an economically constrained scenario, the closure of high-cost palladium mines is foreseen.

The rhodium graph is similar to the platinum graph, amid the significant amount of rhodium produced by upper group two, or UG2, mines on the western limb of South Africa’s well-endowed Bushveld Complex.

“These mines are now nearing the end of their lives and are anticipated to become less competitive as production starts to fall,” Dunne projected further, while emphasising the loss to planet earth of the falling projected availability of PGMs.

“PGMs are very, very special metals. They are very rare and are only found in a few places around the world.

“Their unique catalytic chemical properties are used to make the world a better place,” Dunne said while displaying a slide with an iridium chloride background.

“Iridium is one of the rarest elements on earth, and was named after Iris, the Greek goddess of the rainbow.

“Iridium, together with the ruthenium, were historically considered the minor PGM metals, but their importance is growing, in particular, in the hydrogen economy,” Dunne pointed out.

MANY VALUE-ADDING STAGES

Producing pure PGM metal begins with the mining of ore deposits that typically contain a low concentration of the metals, two to five parts per million, two to five grams per ton.

Following this, the mined ore passes through five stages of physical and chemical beneficiation, ultimately producing high-purity, stable, and saleable PGMs.

To do this, tens of thousands of Southern Africans are employed and very many terawatts of electricity are deployed.

Along with the PGMs often comes valuable base metals and millions of tons of chroma.

Operations have multiple concentrators, smelters, and are linked to local and international refineries.

Mining methods are often mechanised, taking mineworkers away from potentially harmful areas through the use of machines.

Many mining companies invest in local communities and take care of the environment in and around mining operations and mine closure results in far-reaching socioeconomic disruption, which the PGMs industry is clearly seeking to avoid.