Ruthenium highlighted again in what could be another big boost for platinum group metals

Valuable use of ruthenium being researched.

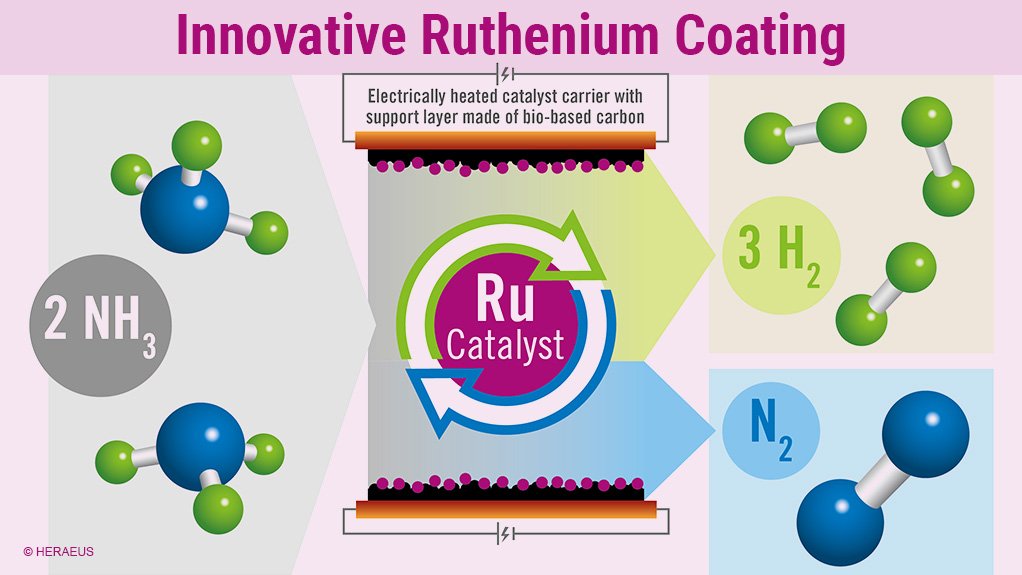

Photo by Inforgraphic: Heraeus Precious Metals

Ruthenium, one of the six platinum-group metals (PGMs), is once again being given major research attention in view of it being exceptionally suited to uplifting the efficiency and sustainability of green hydrogen production from green ammonia.

Late last year, it was a ruthenium-based catalyst that augmented the scarcity of iridium, another PGM, in the production of green hydrogen from water electrolysis.

Now researchers are optimistic that ruthenium will likely boost the recovery of green hydrogen from green ammonia.

The hope is that it will do so as a key ingredient of the latest AmmoCatCoat innovation, which has attracted €2-million worth of three-year public funding from the German Federal Ministry of Education and Research, or BMBF, as part of the Material Hub and Resource Sovereignty funding focus.

“I’m convinced that with AmmoCatCoat we’ll succeed in providing a more efficient and sustainable method for ammonia cracking,” Heraeus Precious Metals’ Dr Konrad Krois stated in a release to Engineering News & Mining Weekly from Hanau.

With platinum and iridium PGMs tending to dominate in the hydrogen space, earlier this year Heraeus and South Africa’s PGMs major Sibanye-Stillwater partnered in exploring new applications for PGMs in the hydrogen economy, focusing on how applications can also profit from the special traits of palladium, one of the six PGM elements.

Increasing demand for hydrogen purification during the production of blue hydrogen is one possible example of a palladium-based application, with further examples including the cracking of hydrogen carriers as well as applications in the semiconductor industry, where high-purity hydrogen is needed as a process gas.

In moving technologies to scale, reliable process efficiency is key, and PGMs are the most efficient providers of such competence.

In this latest ruthenium development, Heraeus will be leading a consortium of six institutes and companies in researching the use of novel, directly heated catalyst modules based on sustainable carbon, amid the energy transition needing solutions that are material-efficient and competitive in operation.

The Heraeus-led project consortium includes project partners such as Fraunhofer ISE, Leibniz Institute for Agricultural Engineering and Bioeconomy, the Centre for Transmission Electron Microscopy, PYREG GmbH, and Purem by Eberspächer, and combines expertise in catalysis, biomass conversion, material characterisation, and surface treatment.

The aim of the project is to provide a practical demonstration of operation under real technical conditions at pilot plant scale. Additionally, scaling concepts will be developed.

For transport, hydrogen can be chemically stored in the form of ammonia and then released. For this chemical reaction, PGM catalysts such as ruthenium are exceptionally suitable.

To make the process as sustainable, efficient and cost-effective as possible, the materials used need to allow operation at low temperature, have high long-term stability, and be used as sparingly as possible, and these project partners are researching how to implement these requirements in a new approach.

The project involves the catalytically active ruthenium layer being applied to an electrically heatable catalyst carrier system, which ensures direct and even heat distribution and heat being brought exactly to where it is needed. The active layer consists of nanoparticles that are finely distributed on a specially tailored carbon material.

Current research results show that the catalytic activity of ruthenium can be markedly improved by using carbon as the catalyst support.

The interaction between the carbon support and the ruthenium nanoparticles should significantly improve the performance of the catalyst before being recycled at the end of its extended useful life to allow further energy savings.

The goal is to achieve maximum ammonia conversion at temperatures below 500 °C, which results in sizeable energy savings in operation – a critical step in increasing efficiency and sustainability of hydrogen production from ammonia, Heraeus pointed out in its release.

The development is focused on a compact design and the longevity and stability of the catalyst.

The carrier itself is also made of a material based on biomass carbons, rendering it more sustainable as well as more efficient and stable in use than is provided by alternative carrier materials.

Green Hydrogen in South Africa

In South Africa, initial production of more than a million tonnes of green ammonia a year is envisaged at the proposed R105-billion Hive Hydrogen project at Coega in the Eastern Cape, headed by former Eskom CEO and Standard Bank chairperson Thulani Gcabashe.

The project presents an opportunity to create a key Hydrogen Valley-type kick-start in a country well endowed with renewable energy, land, port infrastructure and the minerals and metals needed to be a globally competitive green hydrogen producer.

Hive Hydrogen is also collaborating with Itochu Corporation of Japan to develop a least-cost green ammonia solution.

Green electrons and green hydrogen are presenting South Africa with a massive opportunity to reindustrialise, Nedbank CIB head of infrastructure, energy and telecommunications Mike Peo told the recent Green Hydrogen Roundtable.

“There’s an incredible ecosystem that exists around green hydrogen. There are maybe 30 to 40 very specific types of opportunity that can arise as a consequence of building green hydrogen and green ammonia production plants and having molecules that can be utilised,” Peo added.

An example is progressing into the field of green hydrogen fuel cells, which are being envisaged to power large haul trucks used for mining. While a 500 t example has been under trial at the Mogalakwena PGMs mine in Limpopo for many months, Australian mining company and green molecules promoter Fortescue recently publicised that its Liebherr T 264 haul truck is powered by hydrogen as part of its mission to decarbonise heavy industry.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation