Volkswagen Group Africa (VWA) will invest R4-billion in its manufacturing plant in Kariega, in the Eastern Cape. The investment will be used to prepare the plant for the addition of a third model to the company’s production line-up from early 2027.

Latest

sponsored by

Latest News

Sponsored Posts

SPONSORED POST

SPONSORED POST

Latest Multimedia

sponsored by

Receive our free daily newsletter:

Latest News

Renewable woodfibre-based products company Sappi Southern Africa has achieved a GMP+ Feed Safety Assurance (FSA) 2020 certification for Pelletin, a lignin-based animal feed additive, making Sappi...

JSE-listed Calgro M3 Holdings – an entity specialising in integrated residential developments and memorial parks – is expanding its Memorial Parks division with the acquisition of a new park in...

Trade union Uasa has warned that if Gauteng's water disruptions are not addressed soon, the situation could end up as “a second Eskom”. South Africa was introduced to loadshedding in 2007, after...

JSE-listed Afrimat expects to report a 21% to 26% year-on-year increase in headline earnings a share to between 553.6c and 576.5c for the financial year ended February 29. Earnings a share are also...

Technology company ABB has joined investors EDP, ESB, TotalEnergies, Act and DublinBIC in becoming an investor in energy management solutions company GridBeyond, which uses artificial intelligence...

Sponsored Posts

SPONSORED POST

Latest News

The OPEC+ oil producers group, having lost Angola and other players in recent years, is eyeing Namibia for possible membership as it sets up what could be Africa’s fourth-largest output by the next...

The sale by Southern African diamond mining company Petra Diamonds of an exceptional blue diamond in its fifth tender cycle lifted the average prices per carat received 22% higher than those of the...

New York- and Toronto-listed Platinum Group Metals, which is emerging in South Africa’s Waterberg, on Tuesday provided an update on its new light battery technology that points to increasing...

South Africa has taken a preliminary step toward filing a complaint with the World Trade Organization (WTO) against the European Union (EU) over its treatment of citrus imports from the country,...

Illegal connections are one of the leading causes of electricity-related injuries and deaths in South Africa, while also posing a risk of fires and electrocutions in communities. It also adds to...

Sponsored Posts

SPONSORED POST

SPONSORED POST

Latest News

The market development aspect of the platinum group metals (PGM) industry is fundamentally key, it was repeatedly stated at last week’s 2024 Resources for Africa Platinum Day. There is strong...

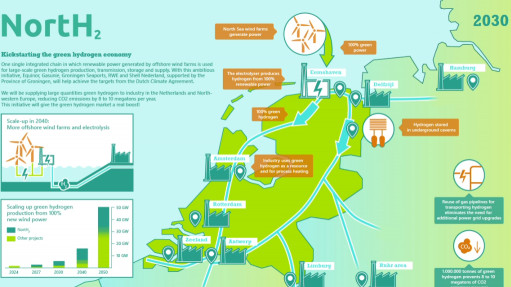

There is sufficient funding available for South Africa to progress its green hydrogen objectives, however, certain elements need to be addressed for this to materialise. This was outlined by...

Despite a forecast of slowing oil demand and a likely peak in consumption by the end of the decade, the International Energy Agency (IEA) warned on Monday of heightened global oil security risks in...

Following last week’s withdrawal of proposed new visa regulations that would have eased the way for skilled workers to come to South Africa, business organisation Business Leadership South Africa...

Young South Africans, aged 35 and younger, are demonstrating a growing preference for private mobility. This is evident in recent WesBank data that shows a consistent increase over the past three...

Sector News

A video round up of this week’s magazine, highlighting our cover story, features and Business Leader.

Deutsche Post’s last night flights transporting mail between northern and southern Germany took place in the early hours of March 28, ending a near 63-year airmail service that had operated since...

- Engineering News Features

- Generators & Standby Power

- Working at Height

- Mining Weekly Features

- Manganese

- Mining in Tanzania

Gauteng’s Far West Rand mining-linked area has always had excellent agricultural potential. In fact, the area had all the makings of a colossal market garden had early mining not dewatered the...

It is estimated that about 2.5 GW of rooftop solar was installed across South Africa last year; a trend that was expected to continue at the start of this year given that some 5 GW of solar panels...

Business Leader

This week we profile Renier van Rooyen, group business systems executive at Multotec, a supplier of mineral processing equipment

While voters will receive three quite different looking ballots on May 29, this seeming increase in choice is not necessarily translating into greater excitement. Yes, some independents will...

Showroom

Rooted in the hearts of South Africans, combining technology and a quest for perfection to bring you a battery of peerless standing. Willard...

VISIT SHOWROOMBooyco Electronics, South African pioneer of Proximity Detection Systems, offers safety solutions for underground and surface mining, quarrying,...

VISIT SHOWROOMBooyco Electronics, South African pioneer of Proximity Detection Systems, offers safety solutions for underground and surface mining, quarrying,...

VISIT SHOWROOMResearch Reports

Projects

Latest Videos

Latest News

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation